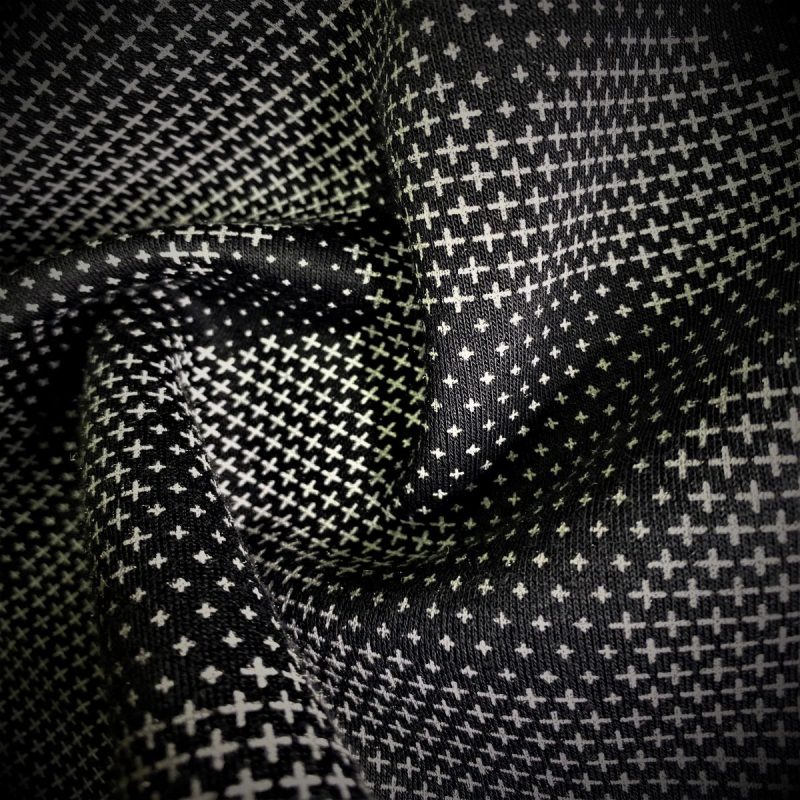

Printed

Printing in textiles is a method applied from past to present and is preferred to give the fabric a different dimension. The use of printed fabrics is quite common and is also aesthetically preferred. These fabrics are one of the expressions of art in textiles, so it has a very important place. There are many different methods used to print. Methods such as block and screen printing are more traditional, while digital prints are more modern choices. Digital printing is very advantageous because every design can turn into a printing by using a printer. Since printing fabrics are indispensable for the textile industry, this article addresses details about what these fabrics are, types of these fabrics, and tips for the use of these fabrics.

What Is Printed Fabric?

This fabric is a process applied on the fabric by paint and with this process, it is tried to create a pattern on the fabric surface. The print is one of the most ideal ways to give the fabric a different look. The type and patterns of the pressure to be made in the fabric vary according to the material generally used. It is quite difficult to print on some fabrics while printing on some is easy. As long as the surface is smooth, most fabrics are made suitable for printing. Knitting and woven fabrics are especially ideal for printing. The tightness of the braids is a factor that also determines the quality of the print. Woven cotton, polyester, and wool fabric are among the most suitable fabrics for printing. Prints can be made with paint as well as digitally. For digital printing, a printer is needed that is only the size of the fabric can pass. Since this method offers many options, it is possible to get a wide variety of prints.

What Are the Types of Printed Fabric?

These fabrics can be divided into different types according to both the technique used and the print made. Some of these fabrics are listed below.

- Block printing is a type of printing that takes its place among these fabrics. Printing on fabric with carved wooden blocks. It is an ideal method for handmade-looking prints. Views that there are ethnic patterns in block printing come to the fore.

- Discharge printing is another type of printing. Usually, this type of printing is preferred for complex patterns. The painted color is removed from the pre-painted fabric and a pattern is left back.

- The type of printing, in which paints are applied on fabric by means of rollers, is called rotary printing. It is a method used in large-scale production and quickly makes it easy to print a large number of prints.

- Finally, in direct printing, paints are applied directly to the fabric with different methods. It is an ideal method, especially for precision designs.

Tips for Handling Printed Fabric

There are some tricks to using these fabrics, otherwise, the prints are worn and deformed. When these details are observed, these fabrics can be used for a long time by preserving the pattern.

- The type of printing is determined by the material used. For this reason, following the instructions given for washing and maintenance is a detail that prolongs the life of the fabric.

- Washing to high degrees and using detergent with a chemical or bleach effect can lead to pressure wear. For this reason, it is the details that should be considered.

- If these textile products require an iron, the ironing temperature should be adjusted correctly, and ironing directly on the print should be avoided. For this, ironing by turning the fabric upside down is the ideal method.

- If you dry the laundry outdoors, you should not expose it to direct sunlight. Otherwise, it may cause the color of the sun prints to fade.

Printed Fabric Characteristics

The prominent features of this fabrics are listed as follows.

- A Very Various Pattern Signature: With the help of digital printing, any pattern can be turned into a fabric print. In this way, it can be applied to design fabrics on a fairly wide scale and can be used for different looks.

- Vivid Colors: Colors are the highlights in printed fabrics. Different patterns are characterized by different colors, so a colorful and dynamic image is obtained.

- Mass Production Opportunity: Large-scale companies are easy to mass produce as the prints are created through machines. This also means that difficult and precise patterns are easily produced from repetition.

- Ease of Printing: Most natural and synthetic fabrics are suitable for printing. Therefore, all kinds of fabrics can be reshaped with printing.

- Different Designs: Patterns can be presented not only visually but also as texture. Different textures and textures can be tried on the fabric and the fabric can be added in size.

- Common Usage Area: Printed fabrics are used in almost any textile product. It is widely preferred in everyday clothing, home textiles, invitation clothing, underwear, decoration, and many more.

As can be seen, printed fabrics are versatile both aesthetically and functionally. If printed fabrics are of interest to you, you can create your own print or discover printed fabrics immediately.