Definition of Fabric Selvage and Its Importance for Textile Projects

December 19, 2023

Textile Chemicals Redefining Color, Comfort, and Durability

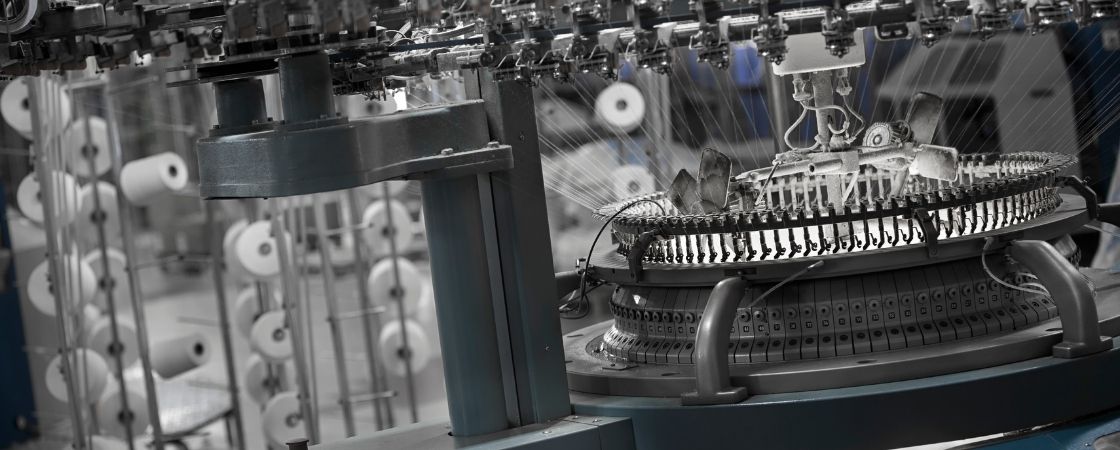

December 25, 2023The roots of knitted fabrics come from ancient times, and various garments are made by hand-knitting. With the development of technology, although hand knitting continues as a hobby, it has not come enough for industrial production. Since knitting fabrics are the most preferred fabrics after weaving, the use of knitting machines has become widespread in its production. These machines, which can be simple or complex, are tools that accelerate the production process and support the production of models with the same pattern. Although some of the simple knitting machines are used in homes as a hobby, they are usually common in areas such as the fabric factory. The description, features and advantages of these increasingly popular and developing machines are discussed in detail in this article.

Table of Contents

ToggleKnitting Machines Description

Knitting machines can be automatic or semi-automatic. They are used to obtain knitted fabrics. Although it is possible to make knitting by hand but machines are very successful both in speeding up the process and in creating more consistent and similar braids. These machines can be of a very simple structure that is not a moving part, as well as a structure that has a lot of moving parts and can be controlled electronically. This variety between these machines allows manufacturers to get many different knitted fabrics that are simple or complex. These machines have great importance for industrial production to get fast production and complex and modest patterns.

Knitting Machine Types

Knitting machines have many different types in themselves. These types are often separated by important features, such as how the machine works or where it is used. Some of the commonly used machines are listed below.

- The threads in the working form of weft knitting machines come transverse or diagonal according to the production direction. This machine has many different types in itself and offers a unique look. Circular knitting, single jersey circular knitting, interlock or jacquards are some of the types of weft knitting.

- Another type of machine is the warp machine and the threads in this machine are moving in the same direction. Parallel threads form loops, and thus knitted fabric appears. There are many types within it, and some of them are raschel knitting and tricot knitting.

- Socks knitting machine is used for the production of specific textile products such as socks and gloves. The needles are designed in a round shape and placed in cylinders. Horizontal loops make knitted textile products such as socks.

- Whole garments machine is an attractive one with its functionality. It is a machine that allows the whole garment to be knitted instead of sewing the pieces of fabric and then joining together. Its area of use is mostly sportswear and underwear. This machine shortens the production process due to the lack of production of piece fabrics and the fact that no joining is required to later combine fabrics.

Essential Knitting Machine Supplies

Essential knitting machine supplies may vary according to the machine used, but some materials are required for each machine. The basic supplies that make a machine work flawlessly are listed below.

- Yarn: The most basic supply necessary for the production of the fabric is yarn, otherwise it is impossible to produce the fabric even if everything is complete. The yarn to be used may differ according to the type of machine and the textile product to be produced.

- Needles: One of the necessary supplies for looping is needles. The number of needles also differs depending on the type of machine to be used. For example, the machine using for socks has a large number of fine needles, while another machine may have fewer and thicker needles.

- Coils: The coil is a material used to keep the yarn stable, and it is used in every machine.

- Roller Holders: This supply has a similar working principle with the coil and is preferred to keep the yarn rollers stable.

- Knitting Needle: This material is used to yarn needles and is found in every machine.

- Guide Bar: The material that guides the thread correctly when the fabric is woven is called the guide bar.

- Pattern Chart: Each machine produces a pattern depending on the principle of working. This material is also used to determine and follow that pattern.

How Does a Knitting Machine Work?

The way these machines work can vary according to the type of machine. This difference is determined by how complex the machine is and the type of machine. In general, how a machine works can be summarized as follows.

- The thread is selected and connected to the machine: Choosing a thread that is compatible with the machine is the first step. The selected thread is drawn through the spool or coil and connected to the machine.

- The thread is passed through the needle: The needle moves according to a specific pattern and the loop is thrown in line with this pattern.

- The pattern is determined: The pattern is determined through the control mechanism. In this way, the direction of the needles is determined.

- The machine is moved: After the pattern is selected, the machine starts to move. This movement can be up and down depending on the pattern.

- Knitted fabric is produced: Threads are passed together in line with pattern and fabric is obtained.

Different Yarns for Different Knitting Machines

Just as with the hand-made mesh, it is very important to choose the right thread that is compatible with the needle in the knitting made in the machine. It is necessary to pay attention to the choice of thread, so as not to waste the yarns and not to damage the machine. The most important criterion when choosing is to choose a thread in accordance with the machine. The threads according to their size are listed below.

- Lace weight yarn: Also known as the lightest type of yarn. It is usually preferred for thin clothing and accessories such as shawls. Since it has a rather thin and light structure, it is necessary to use it carefully, so it is not an ideal choice for beginners. Flat machines and socks knitting machines can work in harmony with these yarns.

- Super fine & light yarn: It is another type of fine yarn and is generally ideal for small size textile products such as baby clothes. It can be easily used in round machines and flat machines.

- Medium yarn: It is often called “aran weight”. Suitable for many machines.

- Bulky and super bulky: They are thick and large yarns, as the name suggests. It is mostly preferred for knitting products such as sweaters, curtains, or blankets. Thick needles are needed to use this yarn.

What Are the Advantages of Knitting Machines?

Knitting machines are very advantageous in many ways. For example, from the point of view of speed and efficiency, it is very useful. These machines produce much faster than hand knitting, which gives a great advantage in industrial production.

Undoubtedly, another advantage is regularity. Unlike hand knitting, a pattern or stitch can be made in a similar way to the previous one. This way, the same product can be produced many times and look better quality. It is quite necessary to ensure consistency in mass production.

These machines also make it easy to get different and complex patterns. With the development of technology, the characteristics of producing complex patterns are also developing. Therefore, even the most complex-looking pattern is possible to produce.

Finally, it is practical to use because it requires much less physical effort than hand knitting. Moreover, it also saves time because the production process is automated.

Advanced Techniques for Knitting Machines

With the development of technology, knitting machines features are also developing. The changing features provide more functionality and ease of use, but it can also be a factor that increases its cost. One of the advanced techniques for these machines is electronic control panels. With computerized technology and control systems, complex projects can be easily executed and knitting patterns can be easily programmed. Computerized pattern programming is quite important for unique pattern production. For complex, unique, and personalized patterns, this programming feature is highly functional. The ability of colors to change automatically is a factor that facilitates the production process. When color changes are done automatically, colorful patterns are formed perfectly.

All these advanced techniques are features that make these machines stand out and support its development over time.